Introduction to Assembling a 12V Lithium Battery Pack

In today’s world, the need for efficient and portable energy solutions is more pressing than ever. Assembling a 12V lithium battery pack using 3.7V 18650 lithium-ion cells is a practical skill that can empower individuals to create customized power sources for various applications, from electric vehicles to solar energy systems. The ability to build your own battery pack not only saves money but also allows for greater flexibility in energy storage solutions.

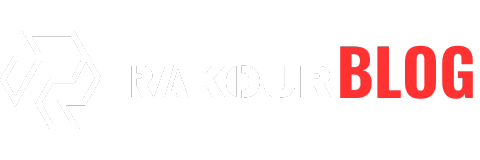

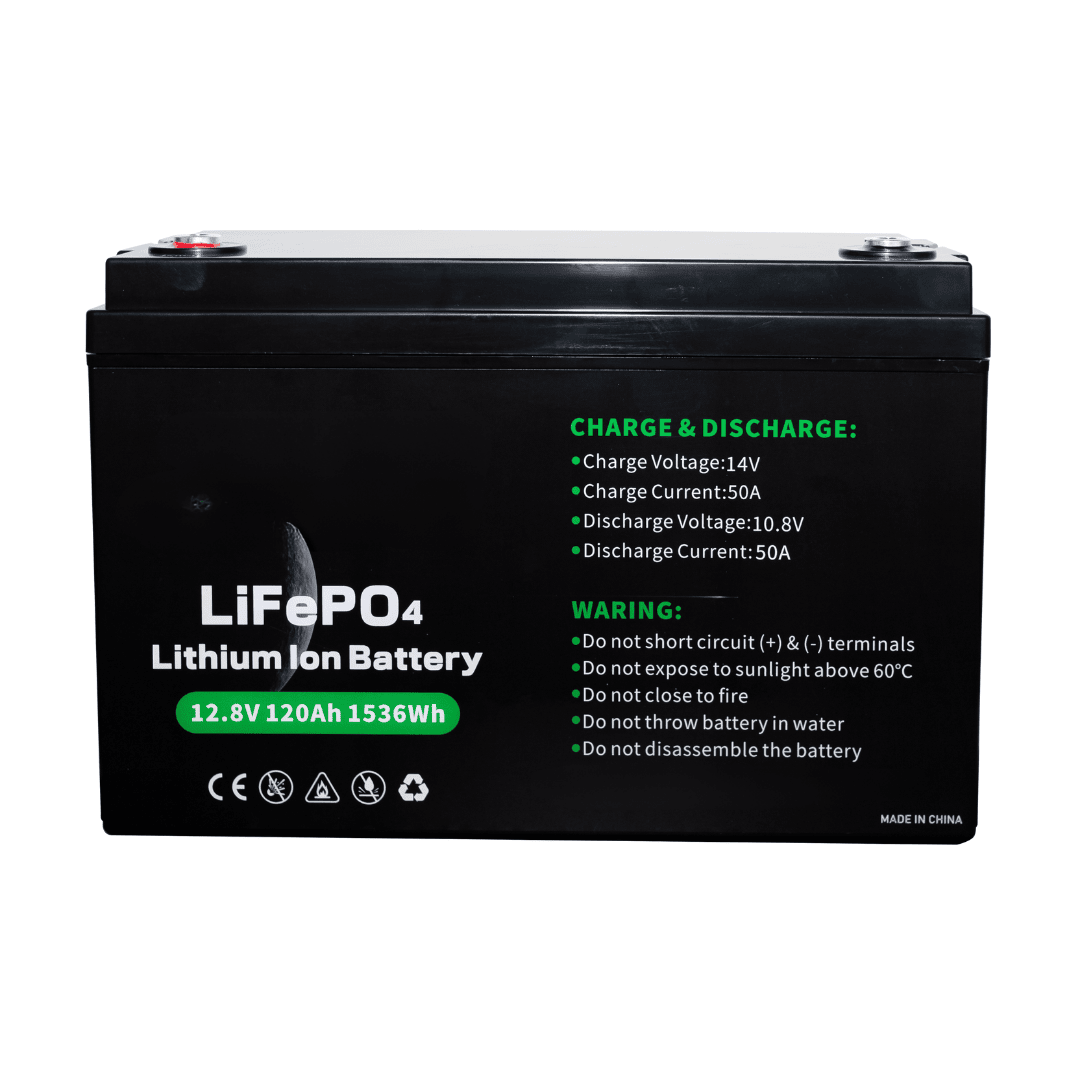

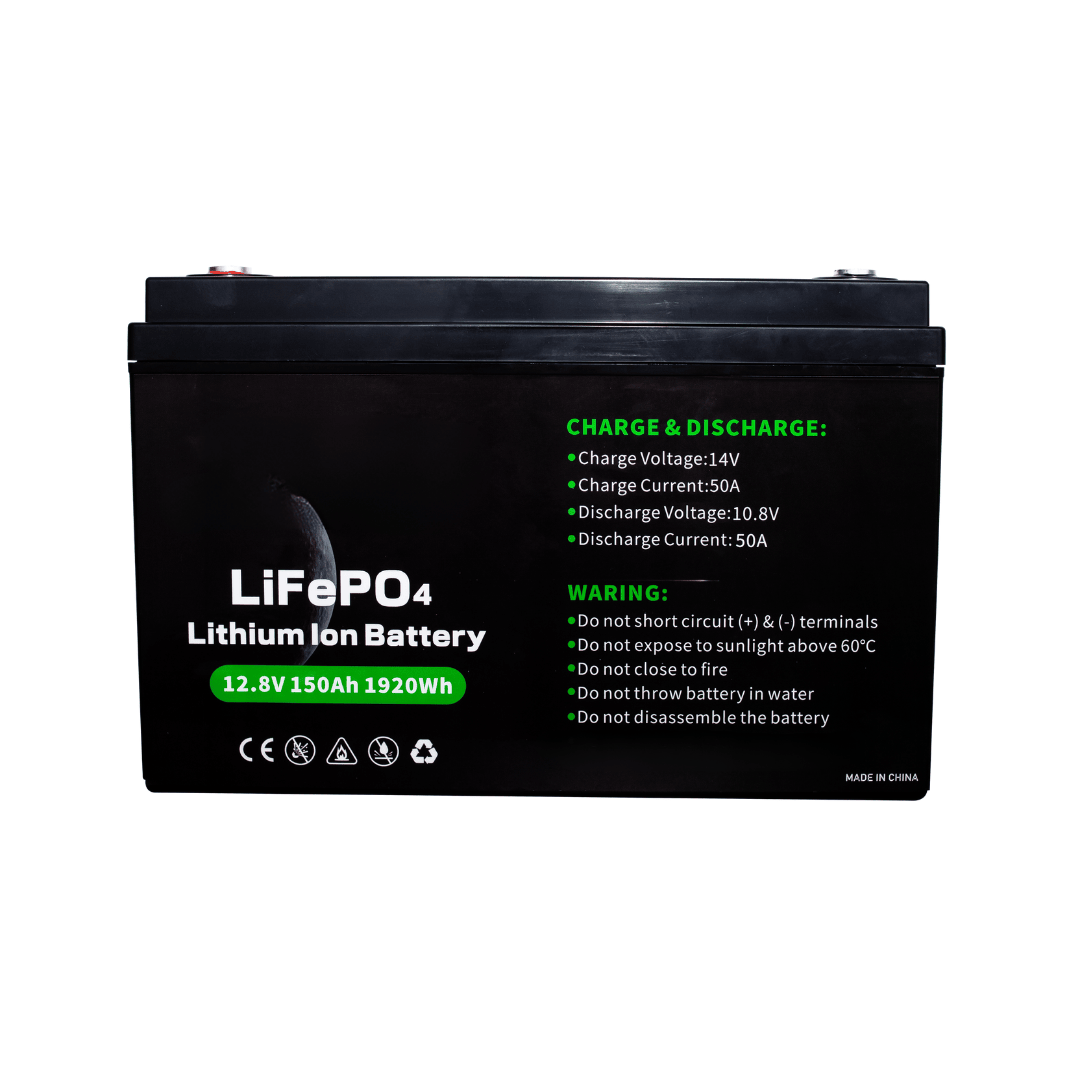

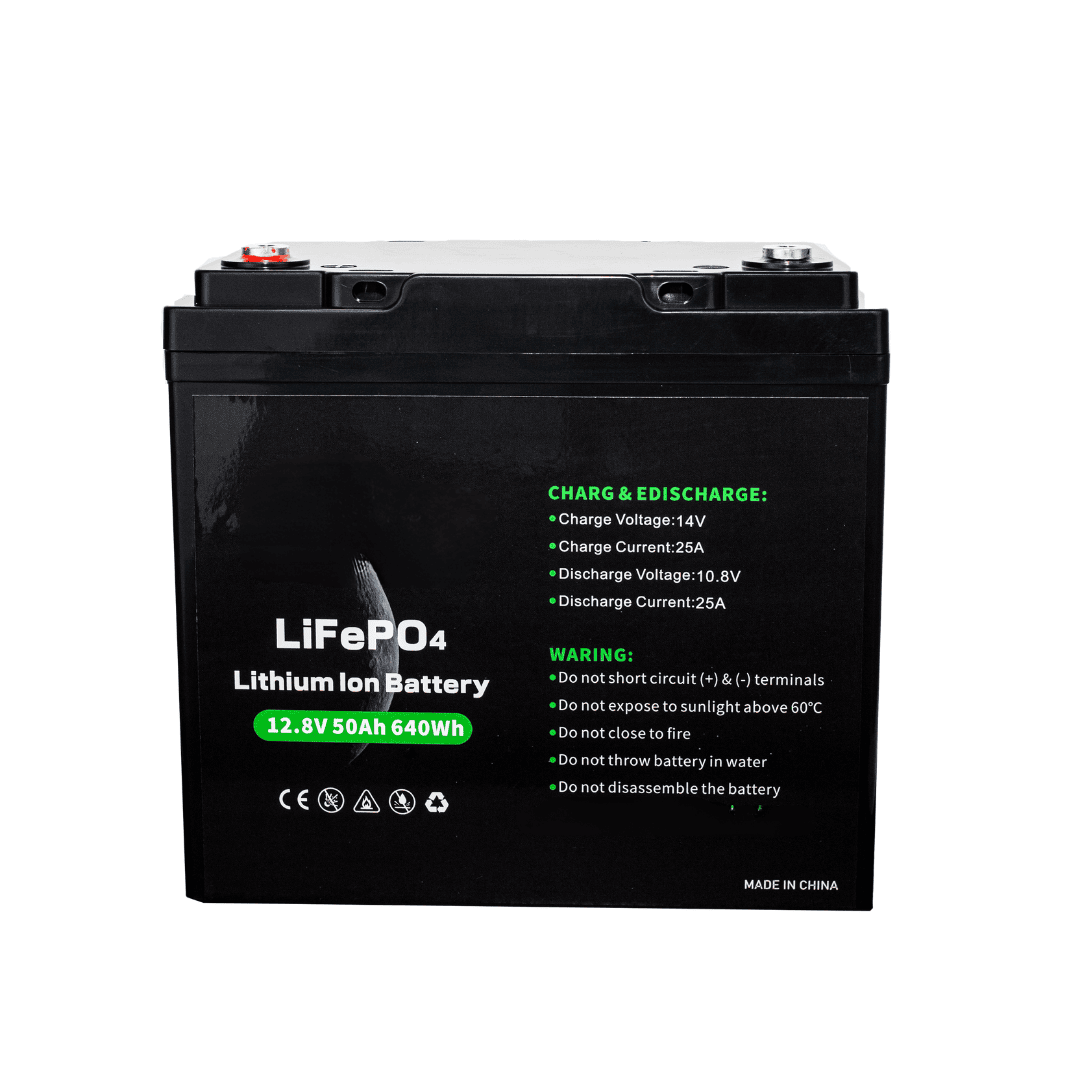

The 12V lithium battery packs are particularly popular due to their high energy density, lightweight nature, and long cycle life. Unlike traditional lead-acid batteries, which are bulky and heavy, lithium batteries offer a compact design that can be easily integrated into numerous devices. Furthermore, with the advent of technologies like the 12V 100Ah lithium battery, users can achieve substantial power output without compromising on space or weight.

Throughout this guide, we will delve into the intricacies of assembling a 12V lithium battery, highlighting key materials, detailed assembly instructions, and essential safety precautions to ensure a successful build. Whether you’re a hobbyist or an enthusiast looking to enhance your knowledge, this guide will equip you with the expertise needed for your project.

Understanding the Basics of a 12V Lithium Battery

To effectively assemble a 12V lithium battery, it is vital to grasp its components and their functionalities. A typical lithium-ion battery pack consists of several critical elements that work in harmony to deliver reliable power.

A. What is a Lithium-Ion Battery?

Lithium-ion batteries are rechargeable energy storage devices that utilize lithium ions as the primary charge carriers. They operate based on the movement of these ions between the positive and negative electrodes during charging and discharging cycles. The benefits of lithium-ion technology include:

- High Energy Density: Lithium batteries can store more energy in a smaller volume compared to other battery types.

- Low Self-Discharge Rates: They retain charge longer when not in use, making them ideal for applications requiring infrequent recharging.

- Long Cycle Life: With proper care, these batteries can endure hundreds to thousands of charge cycles before significant capacity loss occurs.

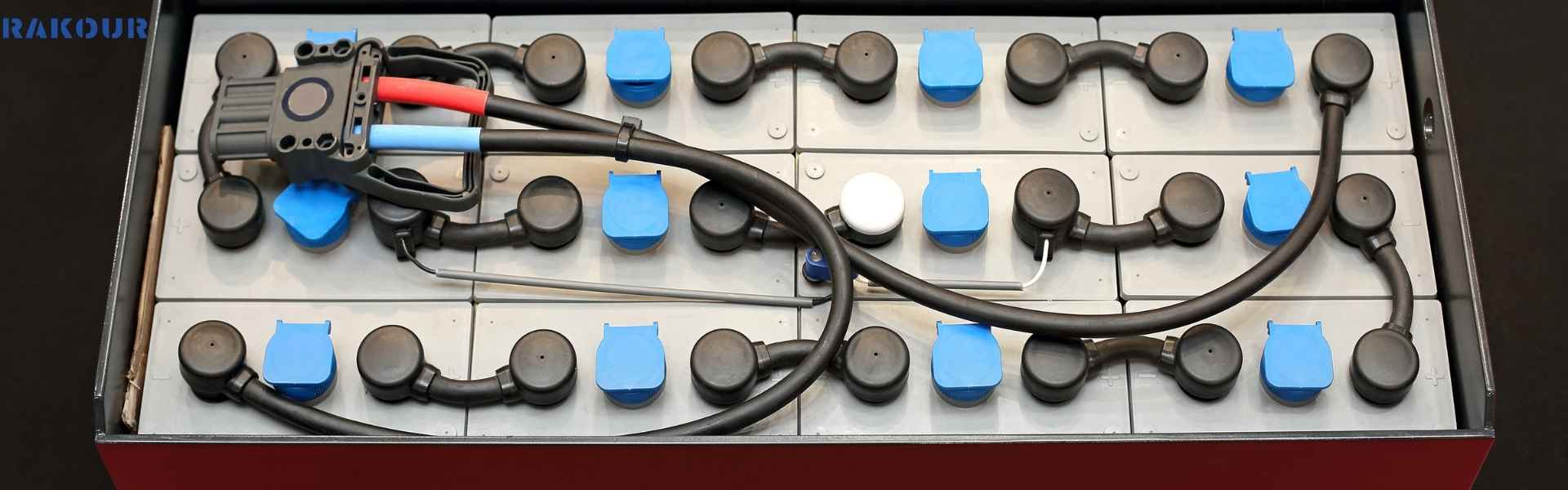

B. Key Components of a Lithium Battery Pack

When building your own 12V lithium battery pack, understanding its essential components is crucial:

- 18650 Cells: These cylindrical cells typically have a nominal voltage of 3.7V and vary in capacity, commonly ranging from 1800mAh to 3500mAh. Selecting high-quality cells is vital for optimal performance.

- Battery Management System (BMS): A BMS is essential for monitoring each cell’s voltage and temperature, ensuring safe operation by preventing overcharging or deep discharging.

- Connectors and Wiring: Reliable connectors and wiring are necessary for establishing secure connections between cells.

- Enclosure: An appropriate enclosure protects the battery pack from physical damage and environmental factors while providing insulation.

Understanding these components will help you make informed decisions during assembly, ensuring that your 12V 100Ah lithium ion battery operates efficiently and safely.

Materials Needed for Assembly

Before embarking on your assembly journey, it’s imperative to gather all necessary materials to ensure a seamless experience. Here’s an extensive list of items you’ll need:

A. List of Essential Tools and Components

- 18650 Lithium-Ion Cells: Choose high-quality cells with desired capacity ratings that match your requirements.

- Battery Management System (BMS): Select a BMS compatible with your configuration (series or parallel) to ensure safety and functionality.

- Nickel Strips: These strips are used for connecting cells together; ensure they are appropriately sized for the current capacity you intend to draw.

- Battery Holder or Spacers: To secure the cells during assembly and provide stability within the enclosure.

- Soldering Equipment or Spot Welder: For making connections; spot welding is preferred as it minimizes heat exposure that could damage cells.

- Heat Shrink Tubing: To insulate connections and protect against short circuits.

- Wires for Connections: Including JST connectors if needed for easy attachment.

- Multimeter: A crucial tool for testing voltage output and ensuring proper connections throughout the process.

- Safety Gear: Gloves and goggles should be worn during assembly to protect against potential hazards.

B. Safety Equipment Recommendations

Safety should always be paramount when working with lithium batteries due to their inherent risks:

- Always handle lithium batteries with care; avoid puncturing or short-circuiting them.

- Use protective gear such as gloves and goggles when assembling your battery pack.

- Ensure good ventilation while working with batteries, especially when soldering or welding.

- If any cell shows signs of damage (swelling, leakage), do not use it; proper disposal methods should be followed.

By ensuring you have all necessary materials and safety equipment on hand, you can proceed confidently to assemble your 12V battery lithium pack, knowing you are prioritizing safety throughout the process. If you have any questions about sourcing materials or need assistance, feel free to reach out through our contact page.

Step-by-Step Guide to Assembling Your 12V Lithium Battery Pack

Assembling your own 12V lithium battery pack can be an exciting DIY project that empowers you to create a reliable power source tailored to your specific needs. Follow these detailed steps for successful assembly:

A. Preparing the Cells

Start by selecting your 18650 cells based on their specifications such as capacity and discharge rate:

- Sort your cells by capacity; ensure they are matched for optimal performance.

- Test each cell’s voltage using a multimeter; they should ideally be close to 3.7V for balanced performance.

- Group cells together based on matching voltages; this ensures uniform charging and discharging characteristics across the pack.

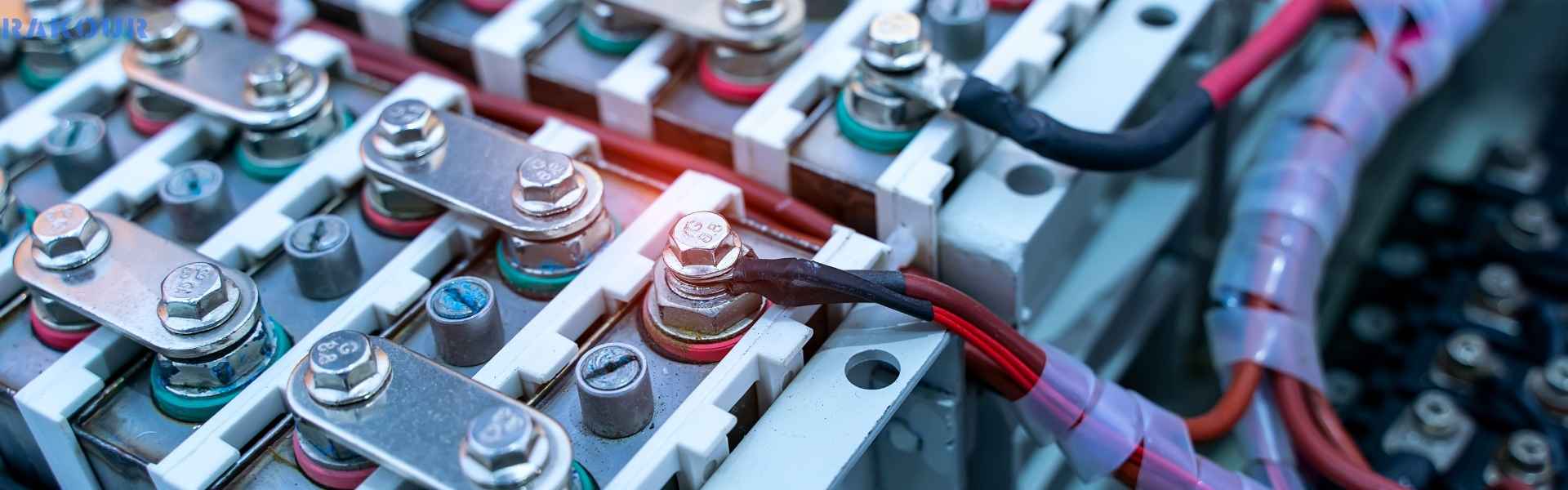

B. Connecting Cells in Series and Parallel

To achieve a total voltage of 12V (or higher), you will connect multiple cells in series:

- Connect four 3.7V cells in series (4 x 3.7V = 14.8V nominal). This configuration provides sufficient voltage while allowing room for full charge levels (up to 12.6V).

- If additional capacity is desired, connect more sets of four cells in parallel; this increases total amp-hour ratings while maintaining voltage levels.

- Use nickel strips to solder or spot weld connections securely; ensure each connection is solid to prevent resistance issues during operation.

C. Integrating the Battery Management System (BMS)

The BMS plays an essential role in maintaining the health of your battery pack:

- Connect the BMS according to its wiring diagram; follow manufacturer instructions carefully.

- Ensure that it monitors each cell’s voltage effectively; this helps prevent overcharging or deep discharging scenarios which could damage cells.

- Check that it provides overcharge protection and cell balancing capabilities; these features are crucial for extending the lifespan of your newly assembled pack.

By following these steps carefully, you’ll set up your battery pack correctly, readying it for final assembly and testing while ensuring safety throughout the process. If you need expert guidance during assembly or want professional assistance, don’t hesitate to contact us through our contact page.

For further insights into series and parallel configurations, consider visiting Battery University.

Finalizing Your Battery Pack

Once you’ve assembled your cells and integrated the BMS, it’s time to finalize your battery pack:

A. Insulation and Enclosure Options

Proper insulation is crucial for safety:

- Use heat shrink tubing over all exposed connections; this prevents accidental short circuits.

- Ensure that no metal parts are left exposed that could cause shorts or electrical hazards during operation.

- Place the assembled cells into an appropriate enclosure; consider using foam padding or other materials for added protection against shocks or vibrations during use.

B. Testing Voltage Output

Before putting your new battery pack into use, conduct thorough testing:

- Use a multimeter to measure total voltage output across terminals; confirm it matches expected output (around 14V when fully charged).

- Check individual cell voltages through the BMS interface if available; this ensures all cells are functioning properly within their specified ranges.

Finalizing these steps ensures that your newly assembled 12V lithium battery pack is safe, functional, and ready for deployment in various applications—from powering tools to supporting renewable energy systems like solar panels or electric vehicles.

If you’re interested in understanding how 12 volt lithium-ion batteries compare with traditional options like AGM deep cycle batteries, check out our article here.

Charging Your New Battery Pack

Charging your newly assembled battery pack correctly is crucial for longevity and performance:

A. Recommended Chargers for Lithium Batteries

Select a charger specifically designed for lithium-ion batteries with appropriate specifications:

- Look for chargers that provide constant current/constant voltage (CC/CV) charging profiles; this method optimizes charging efficiency while protecting cell integrity.

- Ensure compatibility with your BMS; some systems may require specific charging voltages or connectors—always check manufacturer recommendations before proceeding.

B. Best Practices for Safe Charging

Follow these best practices during charging:

- Always charge in a fire-safe location away from flammable materials; consider using fireproof bags specifically designed for lithium batteries.

- Monitor the charging process closely; never leave it unattended while plugged in—this helps catch any issues early before they escalate into serious problems.

- Disconnect once fully charged; avoid overcharging as it can damage cells or create hazards—most BMS systems will handle this automatically but remain vigilant nonetheless.

By adhering to these guidelines, you will maintain optimal performance from your new 12V 100Ah lithium ion battery, ensuring it serves you well over its lifespan while minimizing risks associated with improper handling or charging practices.

If you’re considering whether to use a lithium battery instead of a regular car battery, our article here provides valuable insights into this decision-making process.

Troubleshooting Common Issues

Even with careful assembly, issues may arise during operation; being prepared can save time and frustration:

A. Identifying Voltage Drops

If you notice diminished performance or lower than expected output:

- Check individual cell voltages using a multimeter; identify any weak or faulty cells—this may indicate one cell has degraded faster than others.

- Inspect all connections thoroughly; ensure they are secure without corrosion or damage—loose connections can lead to significant losses in efficiency during operation.

- Evaluate BMS functionality; if it’s not performing as expected, recalibration may be necessary or replacement if malfunctioning entirely—always refer back to manufacturer guidelines when troubleshooting electronics like these systems.

B. Addressing Capacity Problems

If your battery pack isn’t holding charge effectively:

- Assess cell health by conducting periodic checks on each individual cell’s performance metrics—consider replacing any degraded or damaged cells immediately.

- Ensure proper balancing through your BMS; unbalanced packs can lead not only to reduced performance but also premature failure if left unchecked over time—this feature is one reason why investing in quality components pays off significantly down the line!

- Review charging habits regularly; consistent overcharging can reduce overall lifespan significantly—always follow best practices outlined earlier regarding safe charging methods!

By proactively addressing these common issues, you’ll enhance reliability within any assembled 12V 100Ah lithium battery while extending operational life across all applications!

If you’re curious about at what voltage a 12 volt lithium battery is considered dead, our article here discusses important thresholds regarding battery health management.

recommended reading

Conclusion

Assembling a 12V lithium battery pack using 18650 cells is not only rewarding but also provides invaluable skills applicable across various domains—from renewable energy solutions powering homes sustainably today through solar installations down into portable electronics projects enabling greater mobility tomorrow!

In summary, we covered essential aspects including understanding lithium technology fundamentals behind its construction processes involved gathering necessary materials step-by-step assembly instructions safe charging practices troubleshooting tips much more—all critical elements creating effective power sources tailored individual needs!

With this knowledge at hand now equipped embark upon DIY journey into world lithium-ion batteries! Whether powering gadgets building renewable energy systems this skill serves well technology continues evolving toward more efficient energy solutions!

Learn How RAKOUR Can help you deploy

future-proof energy

Our team of energy storage experts will take the time to fully understand your business, challenges , and opportunities.

How to Hook Up Golf Cart Batteries: A Comprehensive Guide

Learn how to safely and effectively hook up golf cart batteries in this detailed guide.

What is LFP Battery? Features and Benefits

What is an LFP battery? LFP, or lithium iron phosphate battery, is a type of

Recycling Li Ion Battery: What to Know

Discover the essential aspects of recycling li ion batteries, including the processes, benefits, and innovations

What are the uses of a 12V lithium ion battery?

The 12V lithium battery is a key player in modern energy solutions, known for its

How to Recondition Golf Cart Batteries: A Comprehensive Guide

Learn how to recondition golf cart batteries effectively to restore their capacity and extend their

Top 10 Lithium-Ion Battery Manufacturers

The global lithium-ion battery market is led by CATL, which holds a 37.7% market share

FAQs