Determining Voltage and Capacity for Your Golf Cart

Understanding Voltage Requirements

When building a golf cart battery, the first step is to determine the voltage needed. Most golf carts operate on either 48V or 36V systems. For a 48V battery pack, you will typically use 18650 lithium batteries, as they provide the necessary power and efficiency. Understanding the voltage requirement ensures that your battery pack can deliver the performance needed for your golf cart’s motor.

Assessing Capacity Needs

The capacity of your battery pack is crucial for performance. Golf carts generally require a capacity between 20Ah and 60Ah, depending on usage and desired range. For example, if you need a 48V battery with a capacity of 20Ah, you’ll need to calculate the number of 18650 li-ion batteries required to achieve this.

Calculation Example

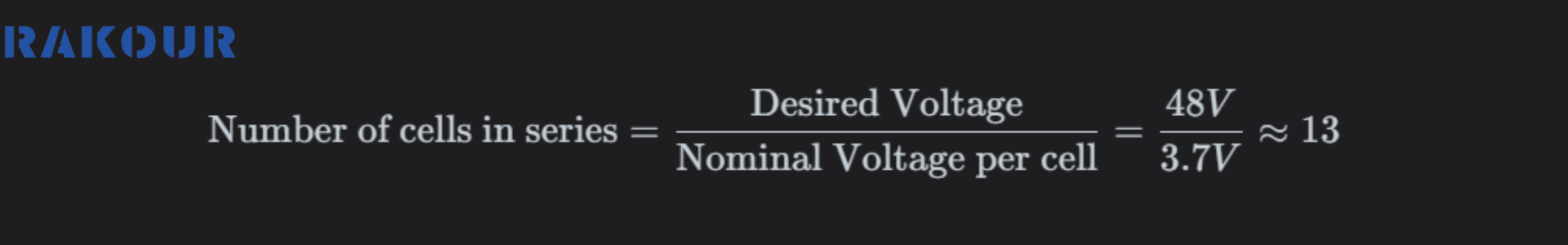

Each 18650 battery has a nominal voltage of 3.7V. To achieve a 48V battery pack, you will need to connect 13 cells in series, as calculated below:

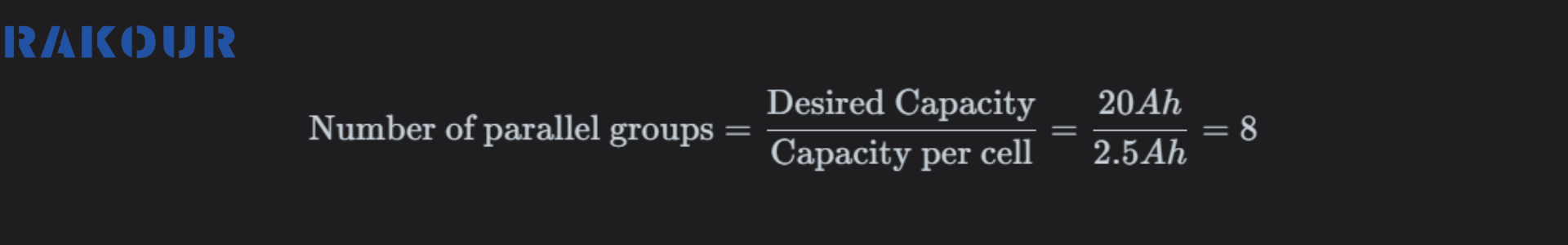

For capacity, if each 18650 cell has a capacity of 2.5Ah, to achieve 20Ah, you would need to connect cells in parallel. The number of parallel connections can be calculated as follows:

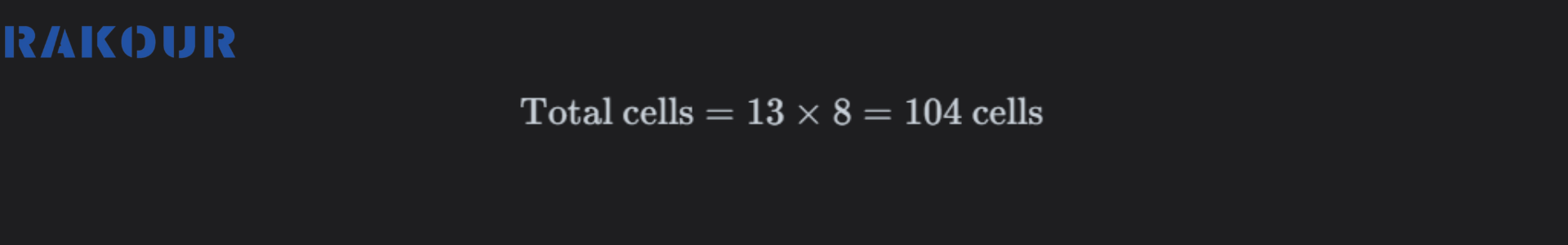

Thus, for a 48V battery pack with 20Ah, you would need 13 cells in series and 8 parallel groups, totaling:

Planning Your Battery Pack Configuration

Series and Parallel Connections

To reach the desired voltage and capacity, you will need to plan a configuration of series and parallel connections. For a 48V battery pack with a capacity of 20Ah, you will need 13 cells in series (2012S) and 8 sets of these in parallel.

Example Configuration

For a 48V pack with a capacity of 20Ah, you would connect 13 cells in series and create 8 parallel groups. This means you would need a total of 104 cells in your 18650 battery pack. Each parallel group will ensure that the overall capacity meets your requirements while maintaining the voltage.

Importance of Configuration

Proper configuration ensures that your 18650 li-ion battery pack delivers consistent power and longevity. A well-planned layout will also simplify the assembly process and enhance safety during operation.

Purchasing Essential Components

Sourcing 18650 Batteries

Once you have your configuration planned, the next step is to purchase high-quality 18650 lithium batteries. Look for reputable suppliers who provide batteries with good cycle life and safety ratings. It’s essential to ensure that the batteries are authentic and meet the required specifications for your project.

Additional Components Needed

In addition to 18650 batteries, you will need a battery management system (BMS), an electric vehicle charger, appropriate wiring, and a suitable enclosure to house your battery pack. The BMS is crucial for monitoring the battery’s health and ensuring safe operation.

Ensuring Quality and Safety

When purchasing components, prioritize quality and safety. A good BMS will help monitor and balance the charge in your 18650 battery rechargeable setup, preventing overcharging and enhancing battery life. Additionally, ensure that the charger is compatible with your battery specifications.

Assembling the Battery Pack

Connecting the Cells

Start assembling your battery pack by connecting the 18650 li-ion batteries in the planned series and parallel configuration. Use high-quality connectors and ensure that all connections are secure. Proper soldering or use of battery connectors is crucial to avoid resistance and potential overheating.

Integrating the Battery Management System

Incorporate the battery management system into your setup. The BMS is crucial for monitoring the performance of your 18650 battery pack and ensuring each cell is charged and discharged evenly. This system will also protect against over-voltage, under-voltage, and short circuits.

Finalizing the Assembly

After connecting the cells and integrating the BMS, securely place the battery pack into an enclosure.

Installing and Testing Your Battery Pack

Wiring to the Golf Cart

Once your battery pack is assembled, wire it to the motor controller and connect other essential components like the throttle, brake, and steering system. Ensure all connections are secure and insulated.

Conducting Thorough Testing

Before taking your golf cart for a spin, conduct comprehensive testing of the entire electric vehicle system. This step is vital to ensure everything functions correctly and safely.

Charging Before First Use

Finally, install the charger and charge your battery pack fully before the first use. This ensures that your 18650 battery is ready to deliver optimal performance from the start.

Conclusion

Building a golf cart battery with 18650 batteries can be a fulfilling project that enhances your cart’s efficiency and performance. By following these steps, you can create a powerful and reliable battery pack tailored to your needs.

The Ultimate Guide to 18650 Batteries and Their Uses

The 18650 battery, a type of lithium-ion battery, has become a cornerstone in various applications

Future Trends in Lithium Ion Battery Technology

This article examines the future of lithium-ion technology, focusing on innovations in rechargeable battery design,

Comparing Lithium Polymer Batteries and Li-ion Batteries

This article provides a detailed comparison of lithium polymer batteries and lithium-ion rechargeable batteries, focusing

FAQs