Understanding the Basics of a 12V Lithium Battery

A 12V lithium battery is an essential component in modern energy solutions, providing efficient power for various applications such as solar energy systems, electric vehicles, and portable electronics. Understanding the intricacies of these batteries can empower you to create your own reliable power source.

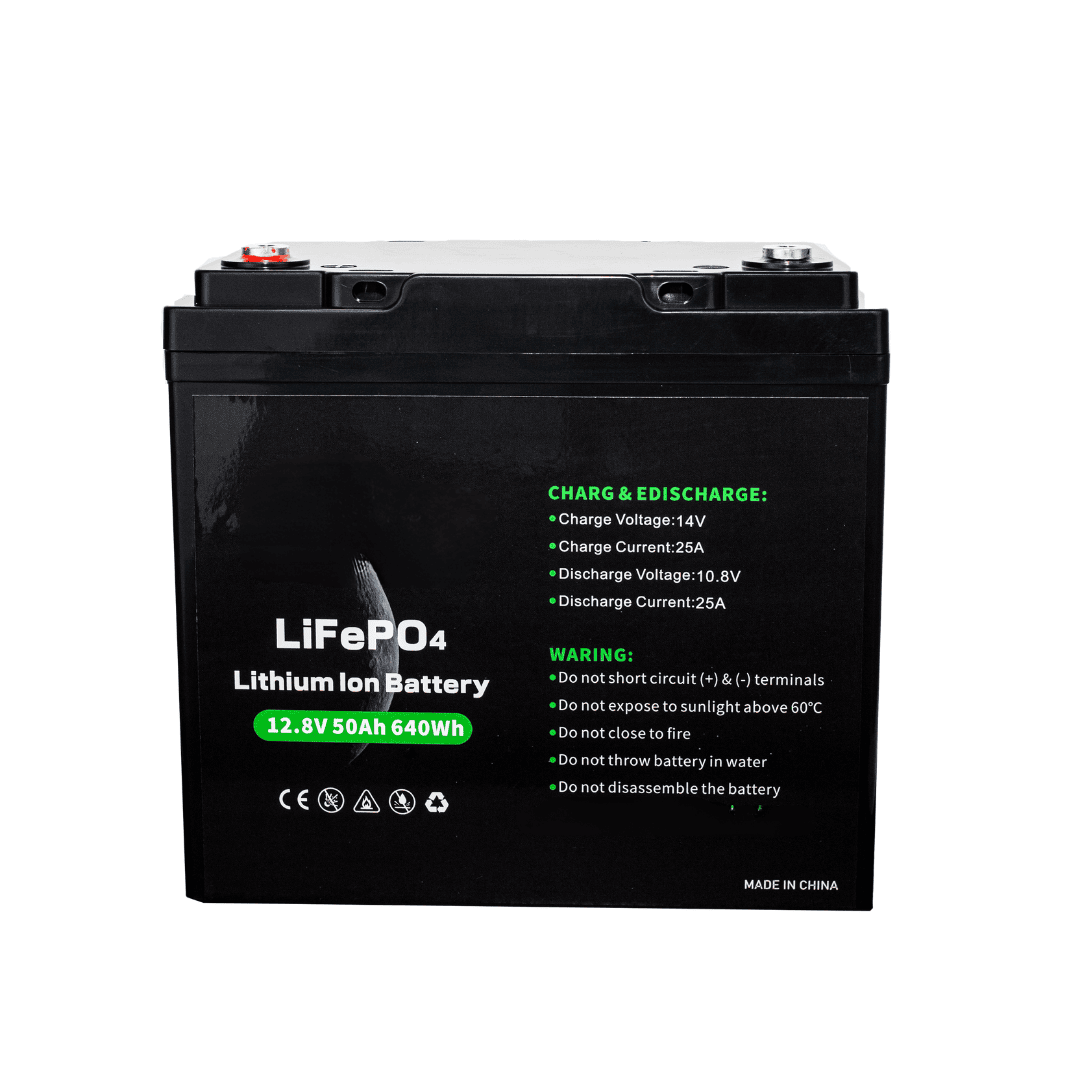

A. What is a 12V Lithium Battery?

A 12V lithium battery typically consists of multiple lithium-ion cells connected in series and parallel configurations to achieve the desired voltage and capacity. The nominal voltage of a single lithium-ion cell is approximately 3.7V, which means that to create a 12V battery, you generally arrange three cells in series (3S configuration). This arrangement allows the battery to provide around 11.1V nominal voltage, which can reach up to 12.6V when fully charged.

In practical terms, a 12V 100Ah lithium battery would consist of several sets of these cells configured to meet specific energy requirements, making it suitable for applications requiring substantial power storage.

B. Key Components of a Lithium Battery Pack

To successfully build a 12V lithium battery pack, you will need the following components:

- 18650 Lithium-Ion Cells: These cylindrical cells are widely used in DIY projects due to their high energy density and availability. Selecting high-quality cells ensures longevity and performance.

- Battery Management System (BMS): A BMS is crucial for protecting the battery from overcharging, over-discharging, and ensuring cell balance during charging cycles. It plays a vital role in maintaining the health of your 12V 100Ah lithium ion battery.

- Nickel Strips: Used for connecting the cells together, nickel strips are preferred for their conductivity and ease of use with spot welding techniques.

- Battery Holder/Spacer: This component secures the cells in place during assembly, preventing movement that could lead to damage or short circuits.

- Insulation Materials: Heat shrink tubing or electrical tape is essential for preventing short circuits by insulating exposed connections.

- Wires and Connectors: These are necessary for connecting the battery pack to your load and for charging purposes.

Understanding these components will help you assemble a reliable and safe 12V battery lithium pack tailored to your needs.

How to Assemble a 12V Lithium Battery Pack

Building a 12V lithium battery pack involves several steps that ensure safety and functionality. Here’s how to do it effectively:

A. Selecting the Right Cells (18650)

When selecting 18650 cells, opt for high-quality batteries from reputable manufacturers. Ensure that all cells have similar capacities (measured in amp-hours) and voltages for optimal performance. Inspect each cell for any physical damage or signs of wear before use; this attention to detail can prevent future complications.

B. Configuration: Series and Parallel Connections

To achieve a 12V output, connect three 18650 cells in series. The connection process involves:

- Connecting the positive terminal of the first cell to the negative terminal of the second cell.

- Connecting the positive terminal of the second cell to the negative terminal of the third cell.

- The remaining free terminals will serve as your positive (+) and negative (-) outputs for the battery pack.

If you require higher capacity (e.g., 4.5Ah), consider using multiple sets of three cells in parallel (3S2P configuration). This setup allows you to double or triple your capacity while maintaining the same voltage output, making it ideal for applications needing more power without increasing size significantly.

For a detailed guide on assembling your battery pack, check out our article on how to assemble a 12V lithium battery pack with 3.7V 18650mAh cells.

Battery Management Systems (BMS)

A BMS is an integral part of any lithium battery setup, particularly in a 12V lithium battery pack.

A. Importance of BMS in Lithium Batteries

The primary function of a Battery Management System is to monitor and manage individual cell voltages, ensuring they remain within safe limits during charging and discharging cycles. This prevents issues such as overcharging, which can lead to thermal runaway—a dangerous condition that can cause fires or explosions if not properly managed.

For further insights on how BMS technology enhances safety in lithium batteries, you can explore detailed articles on Battery University.

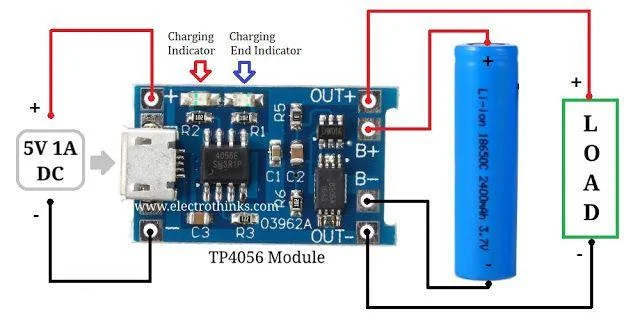

B. How to Integrate BMS into Your Battery Pack

Integrating a BMS into your battery pack involves several steps:

- Choose a BMS that matches your configuration (e.g., a 3S BMS for three cells in series).

- Follow the wiring diagram provided with your BMS carefully.

- Connect each cell’s terminals to the corresponding BMS input.

- Ensure all connections are secure before proceeding with insulation and housing.

By incorporating a BMS, you significantly enhance the safety and longevity of your 12V 100Ah lithium ion battery, allowing it to perform optimally across its lifecycle.

If you’re looking for expert advice on selecting or integrating a BMS into your setup, don’t hesitate to reach out! Contact us today for guidance tailored to your needs.

Safety Precautions When Working with Lithium Batteries

Handling lithium batteries requires caution due to their volatile nature if mishandled.

A. Handling Lithium Cells Safely

Always treat lithium-ion cells with care; they can be dangerous if short-circuited or punctured. Wear safety goggles and gloves when assembling your battery pack, especially when working with tools like spot welders or soldering irons.

B. Common Mistakes to Avoid

- Avoid mixing cells from different manufacturers or capacities.

- Do not exceed recommended charging voltages; use a charger designed specifically for lithium batteries.

- Ensure proper ventilation when charging; avoid charging indoors if possible.

- Monitor temperatures during use; if any cell gets excessively hot, disconnect it immediately.

For more information on battery safety protocols, refer to resources provided by UL Research Institutes.

By adhering to these safety precautions, you can minimize risks associated with building your own 12V lithium battery pack while ensuring safe operation throughout its use.

Testing and Troubleshooting Your Battery Pack

Once your 12V lithium battery pack is assembled, testing its functionality is crucial before use.

A. How to Test Voltage and Capacity

Use a multimeter to measure the output voltage at the terminals of your battery pack:

- Set your multimeter to DC voltage mode.

- Connect the probes to the positive and negative terminals.

- Check that the voltage reads around 11-12 volts; if it’s significantly lower, there may be an issue with cell connections or capacity.

Additionally, perform a capacity test by discharging the pack at a known load while monitoring voltage drop until it reaches its cut-off level (usually around 3V per cell). This ensures that your pack meets expected performance criteria before deployment.

B. Troubleshooting Common Issues

If you encounter issues such as low voltage or overheating:

- Recheck all connections for security.

- Inspect each cell individually for damage or failure.

- Ensure proper functioning of the BMS by checking its indicators or status lights.

Regular testing ensures that your battery remains reliable throughout its lifecycle, especially when used in demanding applications like powering tools or vehicles that require consistent performance from a 12v 100ah lithium battery.

If you’re experiencing persistent issues or need assistance with troubleshooting, our team is here to help! Contact us for expert support tailored specifically for your needs.

Applications of 12V Lithium Batteries

The versatility of a 12V lithium battery pack makes it suitable for various applications across different sectors.

A. Uses in Portable Electronics

These batteries are commonly used in portable devices like laptops, cameras, drones, and power banks due to their lightweight nature and high energy density compared to traditional lead-acid batteries. The compact design allows them to fit into tight spaces while still delivering robust performance.

B. Solar Power Applications

In solar energy systems, a well-constructed 12V lithium battery pack serves as an efficient energy storage solution, allowing users to store excess solar energy generated during sunny periods for use during cloudy days or at night. Their long cycle life makes them particularly advantageous for off-grid solar setups where reliability is paramount.

For insights into how advancements in lithium-ion technology are shaping these applications, check out research from Stanford News on recent developments in energy storage solutions.

Environmental Considerations and Recycling Options

As with all technology, understanding environmental impacts is essential when working with lithium batteries.

A. Impact of Lithium Batteries on the Environment

The production and disposal of lithium batteries can have significant environmental consequences if not managed properly—ranging from resource extraction impacts to pollution from improper disposal methods that can harm ecosystems.

B. Best Practices for Recycling Lithium Batteries

To mitigate environmental harm:

- Always recycle old batteries through certified recycling programs.

- Avoid throwing them in regular trash; many communities have designated e-waste collection days.

- Educate yourself on local regulations regarding battery disposal and recycling options available in your area.

For comprehensive insights into sustainable practices surrounding lithium-ion batteries, consider exploring resources from McKinsey & Company.

By following these guidelines, you contribute positively towards sustainable practices while utilizing technology effectively through your DIY projects involving a 12v 4.5Ah lithium battery, ensuring both performance and environmental responsibility go hand-in-hand as you harness modern energy solutions effectively.

Additionally, understanding at what point your battery needs maintenance is crucial; learn more about this by visiting our article on at what voltage is a 12 volt lithium battery considered dead.

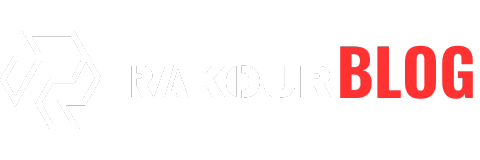

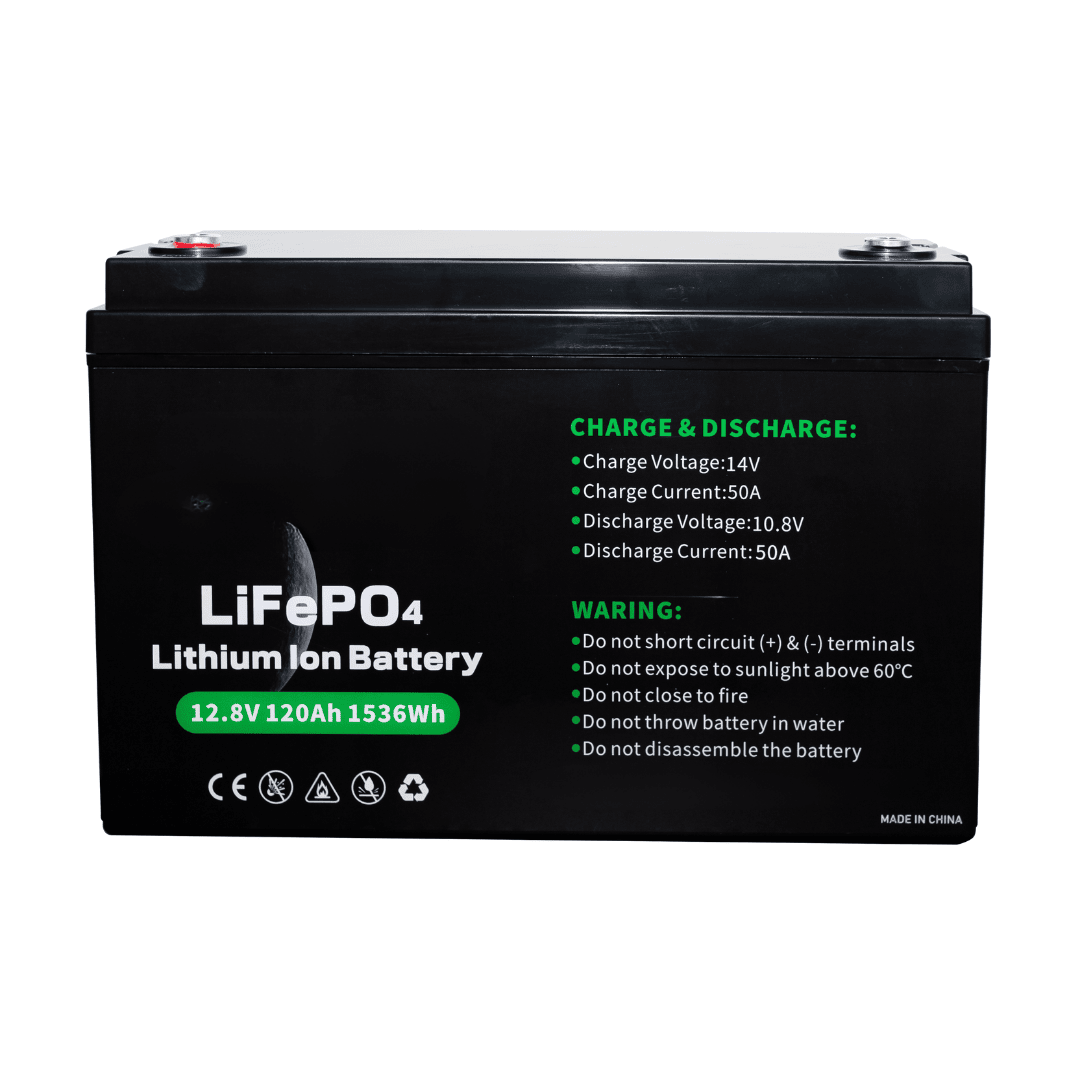

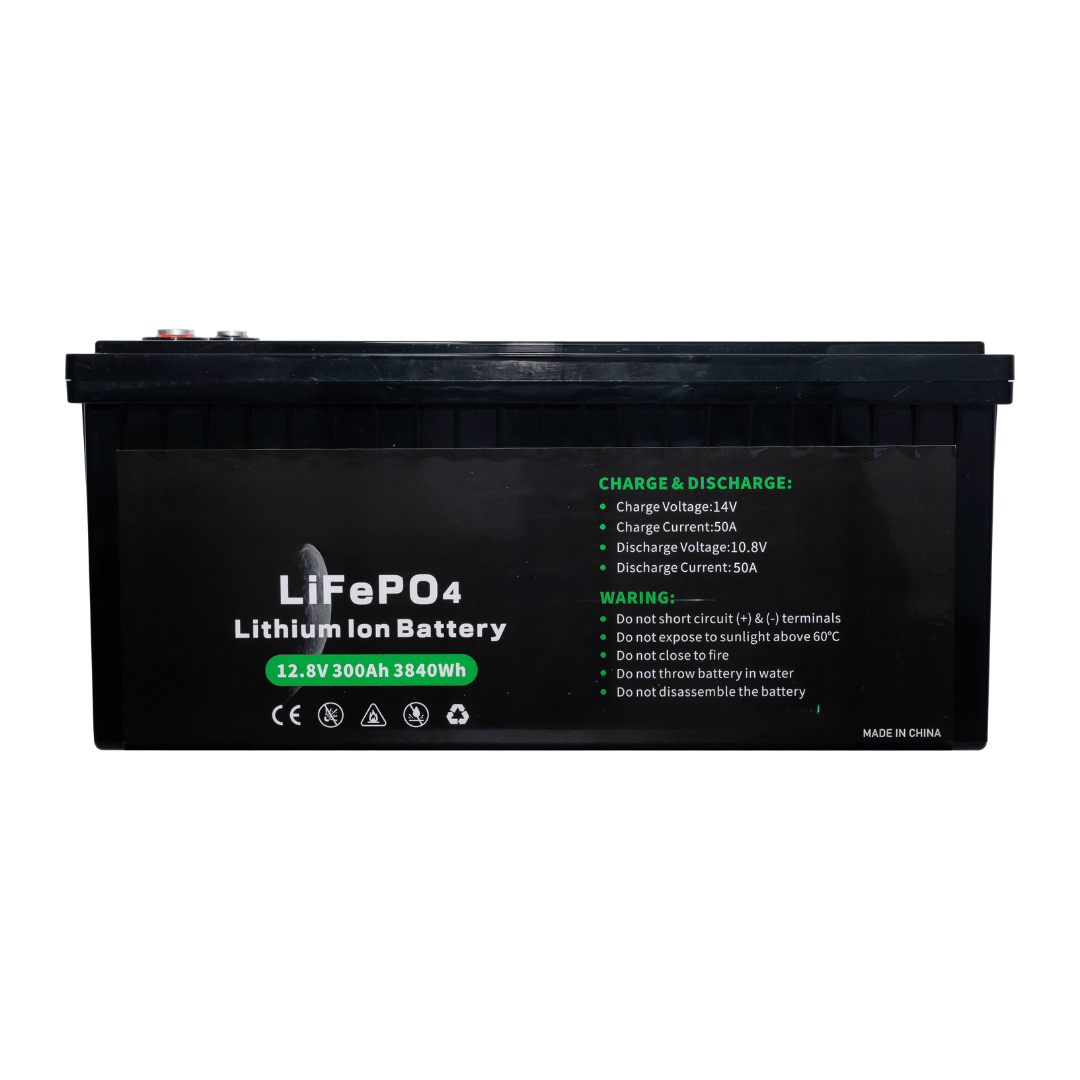

Lear Our Realted Products

recommended reading

Conclusion

In summary, building your own 12V lithium battery pack can be an exciting and rewarding project that provides you with reliable power for various applications. By understanding the components involved and following safety protocols, you can create an efficient energy source tailored to your needs.

Moreover, as technology advances, the use of lithium batteries continues to grow due to their numerous advantages over traditional lead-acid batteries. Embracing these modern solutions not only enhances performance but also contributes to sustainable energy practices.

Learn How RAKOUR Can help you deploy

future-proof energy

Our team of energy storage experts will take the time to fully understand your business, challenges , and opportunities.

What is the difference between a marine battery and a deep cycle marine battery?

Marine and deep cycle marine batteries are essential components for boating, each tailored to specific

LFP Batteries: The Future of Energy Storage

LFP batteries, known for their safety, longevity, and environmental benefits, are revolutionizing energy storage. This

How long will a 12V 100Ah lithium battery last?

12V 100Ah lithium battery, with a capacity of 1200 watt-hours, can power various devices depending

How to Hook Up Golf Cart Batteries: A Comprehensive Guide

Learn how to safely and effectively hook up golf cart batteries in this detailed guide.

Li ion Battery vs. Lithium Phosphate: Key Differences

The debate between li-ion battery technology and lithium phosphate batteries is crucial for various applications,

RV Batteries: What You Need to Know

Explore the essential aspects of RV batteries, from types and maintenance to innovations and environmental

FAQs